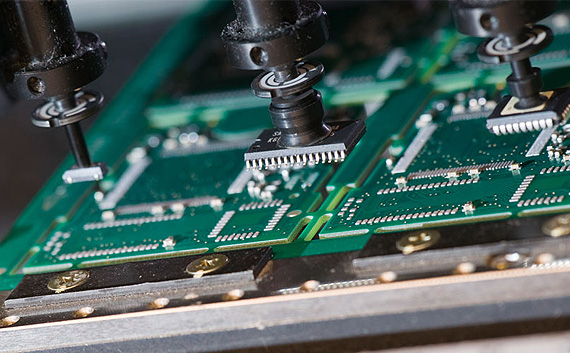

Industrialization and mass production of electronic boards

Thanks to our skills, we are able to calibrate, optimize costs and electronic board manufacturing processes. Whether for prototypes , small, medium or large series, we offer production plans tailored to our clients’ objectives. Our commitment: to offer a quality, fair and balanced offer in terms of cost and time.

We strive at all times to promote “made in Europe” to participate at our level in the competitiveness of our country and to promote exchanges with our customers and local partners.

To ensure the achievement of

your products, we offer:

your products, we offer:

- Optimization of production files.

- BOM review, obsolescence management.

- Realization of test policies (test benches).

- Manufacture of all technology PCBs .

- Procurement of components.

- Traditional assembly, CMS & BGA (electronic board wiring).

- Certificate of conformity.

A quality electronic service

At Anthemis Technologies , we have developed this process that we follow systematically in order to guarantee a quality of impeccable service.

We are adept at ISO methods which are easily applied within our production structure and our partners. Production iterations and optimizations are then quick and relevant.

We support you for the industrialization and manufacture of electronic boards

From electronic design to production through industrialization, our added value is measured at all stages of your project.

We consider all the requirements of your request and we remain a constant source of proposals for the success of our collaborations for electronic production.

Anthemis Technologies offers you a electronic board subcontracting service where we ensure the assembly of your complete electronic products through our international production network. Always perfectly meeting the requirements of quality, deadlines and costs.

Industrialization and optimization of electronic board manufacturing

The transfer of your project from the prototype stage to that of mass production, traditionally recognized as difficult and extremely complex.

Through our network, you have the opportunity to work with an electronic subcontractor for:

- Electronic board manufacturing in small, medium or large series: Prototype mode, CMS report line mode…

- Wiring of strands and wire harnesses

- Tropicalization of electronic circuits

- The mechatronic assembly for the integration of electronic boards in their casings.

Know-how in electronic cables wiring and box assembly

In order to provide the most complete solution possible, we offer our customers the realization of box wire cabling and technical strands .

These are 19-inch type boxes, racks or bays integrating all electrical and electronic equipment to provide electrical or electronic functions for manufacturers.

We also ensure the definition and the realization of mechanical bores, supports and other welded mechanical sheet metal. We also produce plastic parts in 3D printing, powder sintering or injection for large series.

The entire electronic product and its casing is supported by Anthemis Technologies. Robustness, IPxx, thermal or vibration tests are possible for assembled products.

- Realization of strands, wire cabling, wrapping and specific wiring.

- Integration into boxes, racks, racks and other boxes.

- Machining, sheet metal work, bending and assembly of mechanical parts.

- Management of kitting, labels and logistics.

- Complete management of manufacturing files – Reliability / Service / Cost.

Visit our site specializing in PCB manufacturing

Anthemis Technologies offers you the best in electronic board manufacturing services, from rapid prototypes to series in automatic assembly.

Because our customers today face increasingly drastic market demands, time-to-market is a key success factor. We offer electronic board production service for the prototyping phase in the shortest possible time. Our purchasing department processes and organizes supplies in order to achieve logistics related to components. When the development is validated, we adapt our offer for the switch to pre-series and automatic line.

Our people and our processes are RoHS-compliant and we are committed to providing you with ideas and solutions to improve your product definitions through feedback from our production department.

- Single-sided or multilayer 32 PCB (printed circuit board) from class 4 to 7…

- Technologies in Fine Pitch, CMS 1206 to 0402, QFN, BGA pitch 100µm with X-ray

- Wiring of prototype electronic boards (DES / RoHS)

- Project management of SMD [& amp;] reflow process transfer lines for series.

- Vague process control for traditional component boards.

- Product control at the end of the line either by functional bench or mobile probes.